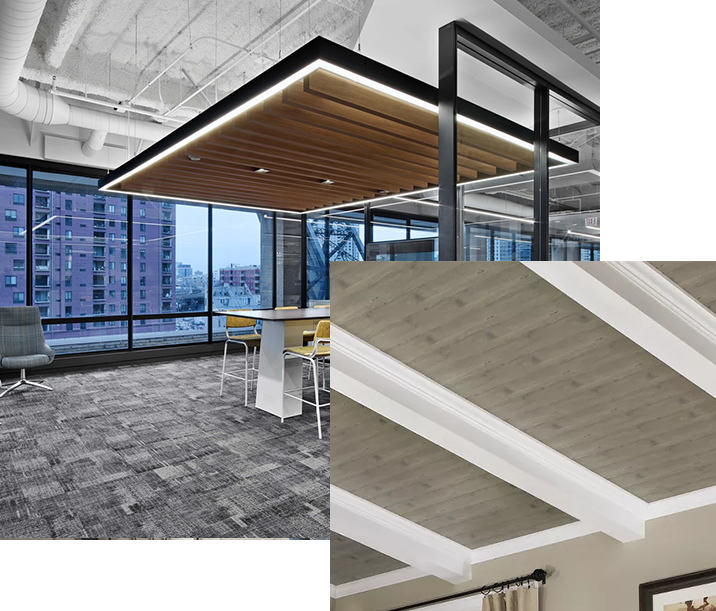

Acoustics

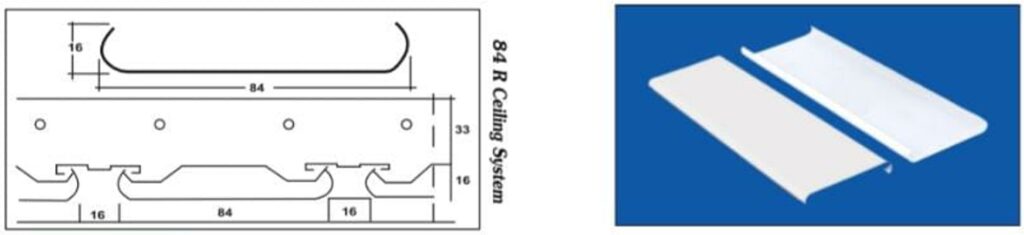

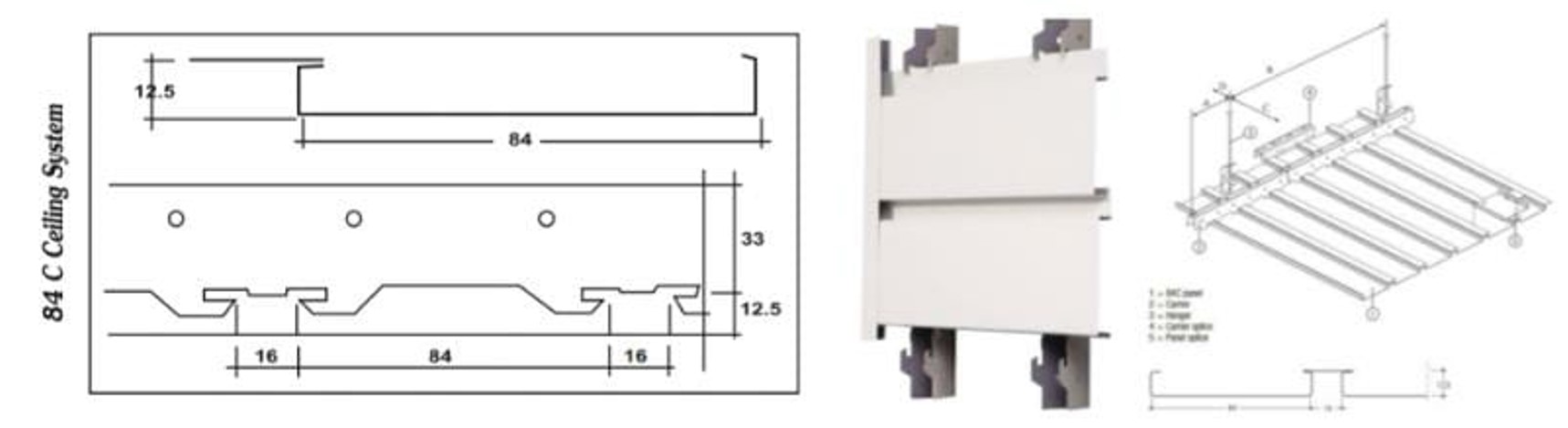

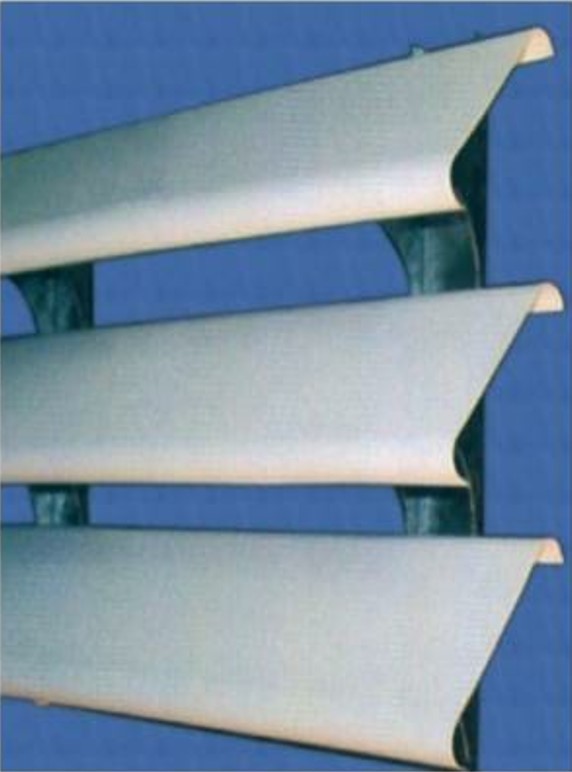

ROYAL KRAFT Metal False Ceiling range comprises different type of perforated panels with an acoustic non woven material factory applied to the rear side of the panels. Due to the controlled sound impedance of this perforated panel, and with a backing air space (ceiling plenum), the ROYAL KRAFT ceiling provides excellent sound absorption properties without the use of any fibrous material behind the perforated panel.

Thermal Insulation

Suspended False Ceilings help in Thermal Insulation of buildings. Due to superior Thermal Insulation property of the ceiling material external heat is kept outside while air-conditioned cooling is preserved inside.